With the sustained and stable development of social economy, the scale of power grid has achieved a leap-forward growth, and will continue to develop at a high speed for a long period of time in the future, which makes the automation specialty face great pressure when carrying out statistical analysis of a large number of miscellaneous data. Meanwhile, there is a lack of effective interconnection between business systems, and automation professionals often need to turn around several systems to get the required information, which is really time-consuming and laborious. Therefore, for such big data and multi-systems, it’s a huge challenge to effectively realize "one-stop" monitoring. In order to solve the above problems, the automatic cockpit emerges at the right moment;. Since 2021, Foshan Power Supply Bureau and DFE Guangzhou R&D Center have conducted in-depth research and cooperation in the field of automatic cockpit. With the business experience accumulated by Foshan Power Supply Bureau in the field of automation and management for many years and the technical reserves of DFE R&D team in big data and Internet of Things, the automatic cockpit has been realized.

The automatic cockpit integrates panoramic data and controls various professional systems, and provides "one-stop" services that comprehensively reflect the key operation state of the power grid, customize the work panel as required and control the closed-loop task flow through the deployment of functions such as panoramic monitoring of business indicators, customized configuration of work desk and task flow management.

1. Business monitoring

Business monitoring focuses on real-time monitoring of business status data, helping automation professionals find and localize problems, and achieving the purpose of automatic operation and maintenance. It is mainly divided into four parts: Main station monitoring, daily operation monitoring, server monitoring and shift task monitoring.

① Main station monitoring

It involves main dispatching, standby dispatching, main network and standby network, including all the key procedures of power business, core operation procedures, business data synchronization status, etc. Through real-time collection service, the operation information of the main station server workstation is collected, and the monitoring result data is encapsulated by Restful specification. The user can monitor the health status of the main station in real time, and capture the abnormal monitoring events in real time through the user-defined alarm generation rules.

② Daily operation monitoring

The daily operation types of automation personnel are recorded. By classifying the daily operations of automation personnel, there are four types: listing, manual number setting, alarm prohibition and interval operation. The monitoring results are displayed on the interface in tabular format. Users can not only visually browse the operation records through the interface, but also automatically form a closed-loop process after the operation items are processed by users.

③ Server monitoring

It involves dispatching, standby dispatching, main network and standby network, and the monitoring dimensions are: network, memory, hard disk, etc. Through real-time collection service, the running status information of server workstation is collected, and the monitoring result data is encapsulated by Restful specification. Users can monitor the health status of the server in real time, and capture abnormal monitoring events in real time through user-defined alarm generation rules.

④ Team task monitoring

Team tasks are divided into daily tasks and special tasks. Daily tasks are short-term tasks, and special tasks are long-term tasks. Show the tasks that will be overdue in the near future through tables, and remind the automation shift members to follow up in time.

2. Customize personal exclusive desktop

Due to the different positions, special duties and attention information of the automation shift members, different cards are customized according to users' needs and stored in the card pool, which is freely chosen by the members. Members from the shift are free to choose the required cards, adjust the placement position, and let the expected data appear in sight; Cards can monitor the key data of the specified system. Behind each card is an independent system or module, which can customize the card jump event, jump to the target system with one button, and open any door exclusively for the shift member.

3. Task management

The task management module takes "management" as the core, and divides several sub-modules according to the above monitoring contents. All the sub-modules are closed-loop controlled according to the work contents of the automation shift members.

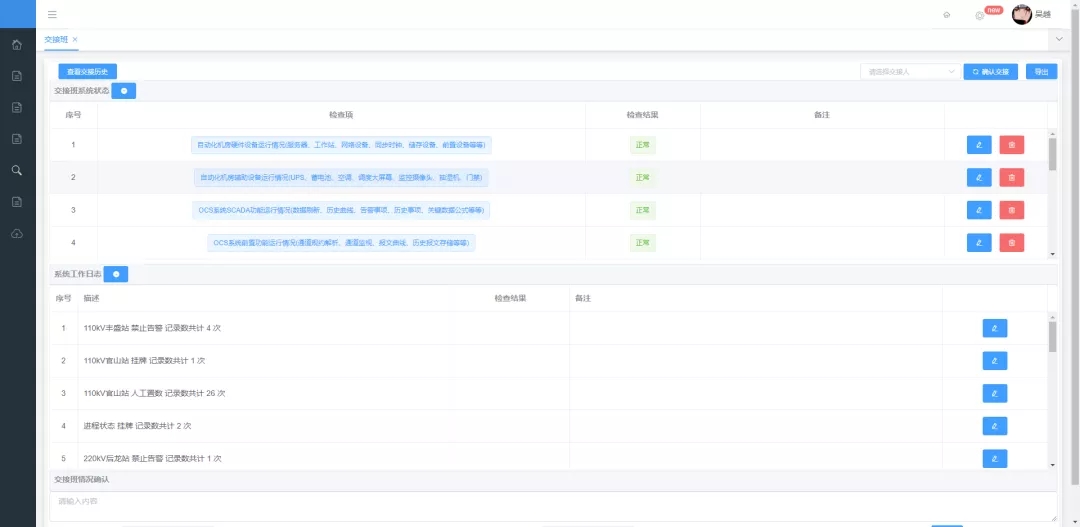

(1) Succession management

Every week, the automation shift will select a shift member as the attendant, who will manage all the work during the shift period, including: Dispatcher, tracking the daily operation of the system, tracking the debugging work, etc. During the period of duty, only the personnel on duty have the authority to change the details of duty. On the last day of duty, the personnel on duty next week will be set up by designating the succession person.

The daily work of automation shift members is already very tedious. For repetitive work such as system inspection, it can be as simple as possible. With automatic fault exception capture and automatic closed loop, automatic shift members can easily cope with daily work by simply browsing.

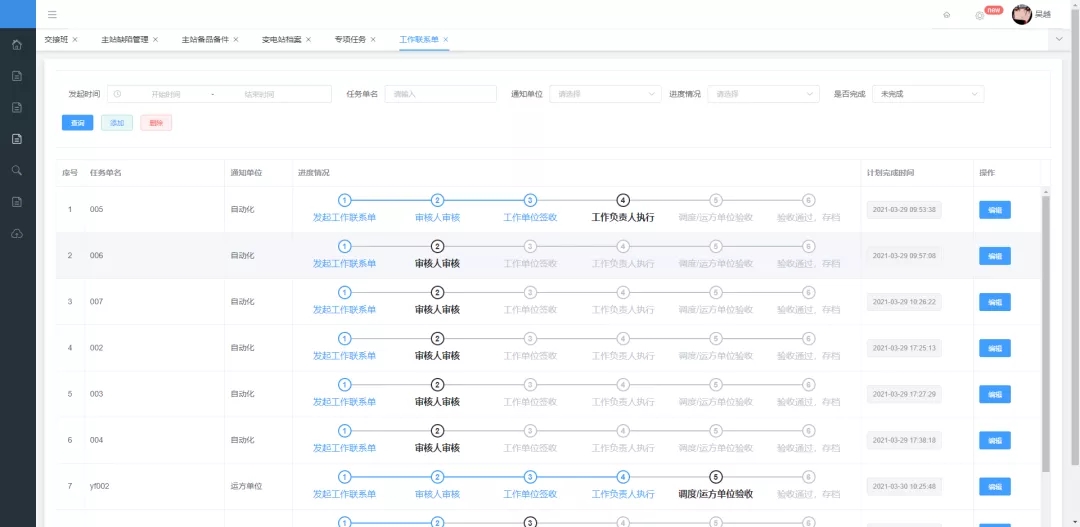

② Management of shipping documents

"Shipment Doc" management module specially provided for dispatchers. Module realizes the permission operation of different personnel in different process for each step of the shipping document. Although the waybill is a module specially developed for dispatchers, it also brings convenience to automation personnel. In addition to cancel the tedious operation-carrying the paper version of the confirmation slip around for confirmation and signature, the operator also eliminates the problem that the paper version is inconvenient to manage.

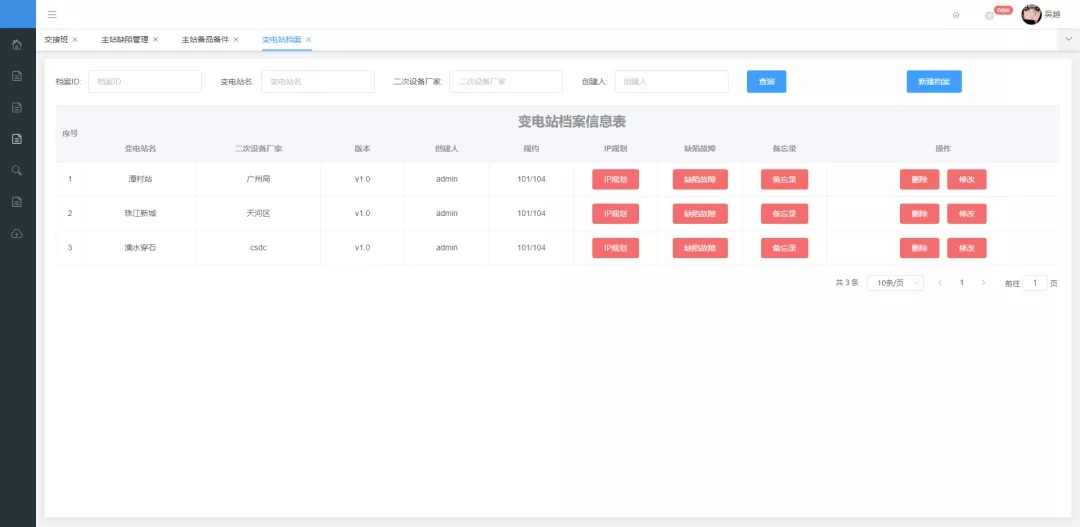

③ Substation file management

Multi-dimensional management module, which takes substation as a unit, records the IP rule list, defects and faults, memos and other information of each substation, and provides an editing interface, so that automatic shift members can operate without documents and realize electronic file management.

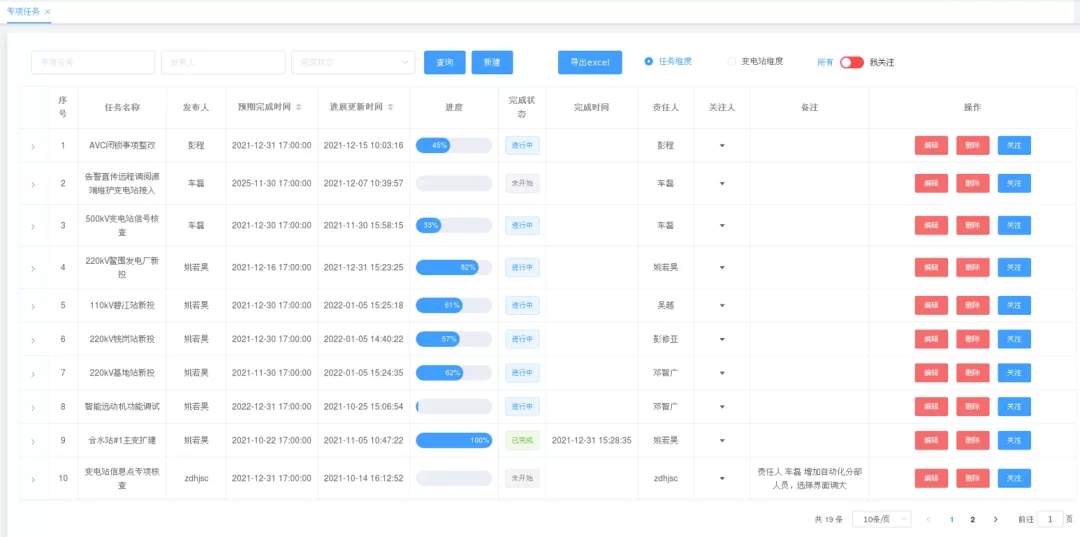

④ Special task management

Support shift members to create task templates, so that shift members can use the templates to quickly edit and publish personal special tasks. Secondly, special tasks can nest subtasks, templates can also nest sub-templates, and the overall task progress is automatically collected by all subtasks. At the same time, the attention mechanism is provided, and the shift members can pay attention to the special tasks published by other shift members. Through this mechanism, the shift members can filter and view the tasks they care about with one click.

4. Closed loop control

Based on the data of the automated business system, the automatic closed-loop management of all defects in the existing system is realized. By fully automatic analysis of the whole process of defect classification, collection, display and alarm, automation professionals are freed from defect analysis and have energy to pay more attention to other automated business management.

Conclusion

Automated cockpit plays the role of data production factors, leads and optimizes business flow with data flow, enhances the flexibility, openness, interactivity, economy and sharing of power grid, and makes the power grid more intelligent, safe, reliable, green and efficient. DFE will continue to dig deep into customers' needs, work closely with customers, explore and advance continuously under the framework of new power system through innovation, and empower the digital transformation of power grid.